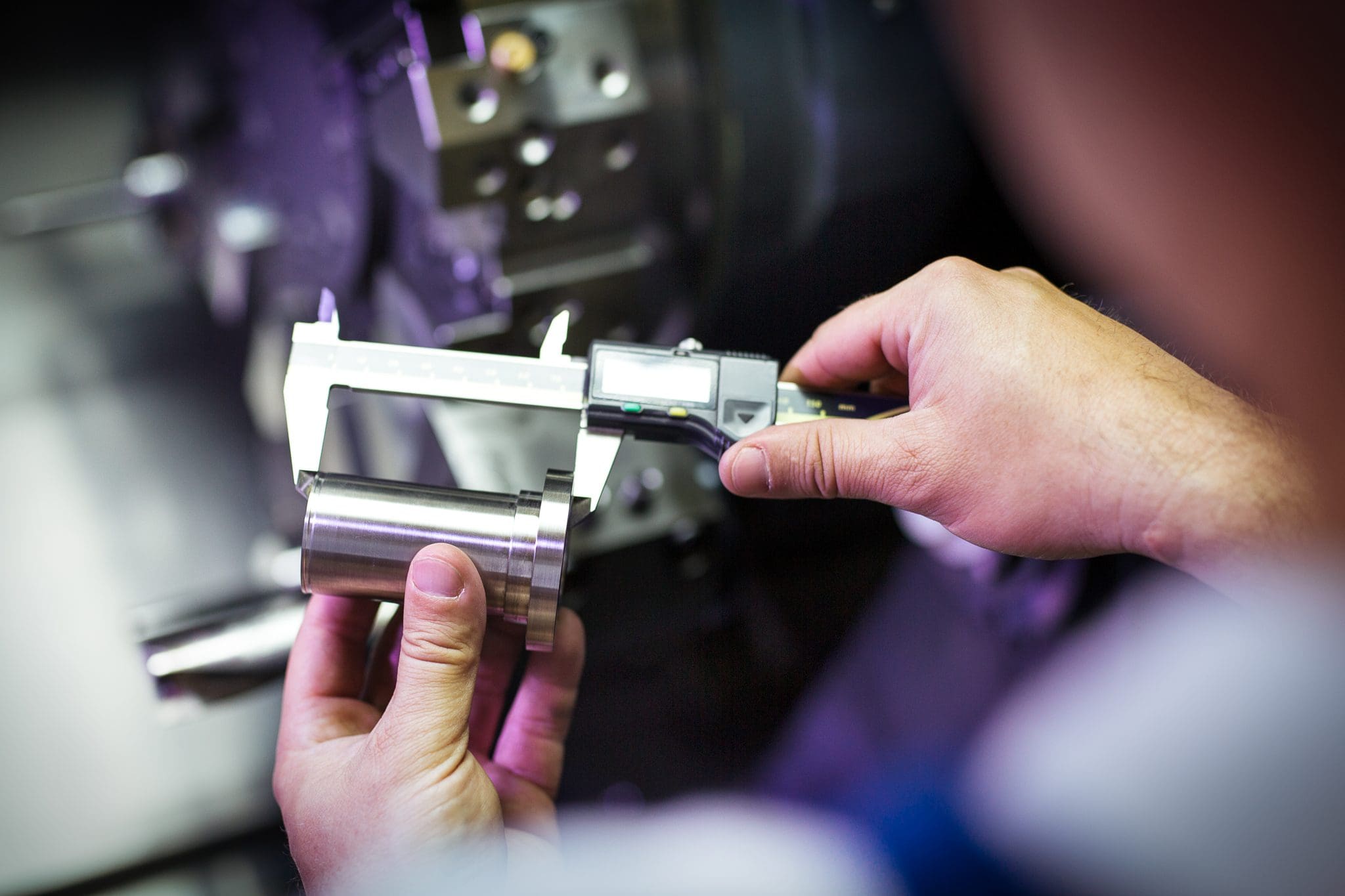

Whether your job is small in scope or a custom solution need requiring special materials, inspection, and precise execution to completion, we can do it all. At CM&T, all jobs are important, regardless of size. We have great relationships with vendors all over the United States that guarantee we have the capability to complete any job.

Machining Capabilities

Corydon Machine & Tool is a full service machine shop to a variety of industries. We place customer satisfaction above all by delivering projects with consistency and dependability. As a result we have built a relationship of trust with our customers. That trust, and the reputation that follows, has to be earned. We welcome the opportunity to build that trust.

MACHINING

- 4 Axis Machining

- Milling & Turning

- Drilling

- Boring

- Surface Grinding

- Broaching

- Welding

SPECIALTIES

- Shafts

- Cores

- Rubber Rolls

- Printing Rolls

CNC Turning

- (2) 13-1/2” X 111” TL-40 MS

- (2) 10” X 40” SL-25 MS

- (1) 10” X 36” B&S EZ Path

- (1) 26” X 144” Chevalier

- (1) 17” x 118” Doosan 3100 ULY with milling capabilities

- (1) 17” x 120” MS NL 3000

Vertical CNC

- (1) 22” X 60” Fryer

- (1) 22” X 60” Mazak

- (1) 20” X 40” Mazak

- (1) 20” X 40” Hurco

- (1) 32” X 144” Komo

- (1) 30” X 120” Mazak

Manual Mills

- (2) Millports

- (2) Bridgeports

- Excell-o

- Comet

- Lagun

- E-mill

- (1) 30” x 70” Kearney & Trecker

Manual Lathes

- (2) 25” x 150” Toolmex over cross slides 16”

- (2) 14” x 60” Toolmex

- (1) 14” x 60” Nova

Horizontal CNC Milling

- 41” X 35” X 38” 4-AXIS MAZAK with 25” pallet changer

Miscellaneous

- (4) Conventional Drill Presses

- (2) 18” Cut-Off Saws

- (1) Surface Grinder (Magnetic Chuck)

- Polishing Lathe

- (1) 100 Ton Hydraulic Roll

- Heat Treating & Nitrite Coatings

- EDM Plunger & Wire

- Cylindrical Grinding 19” x 144”

- Straightening Press

- Swaging

- Welding/Brazing

- Cutting-Plasma

- Blanchard Grinding

- Dynamic Balancing

- Journal Hardened 58-62 RC (flame harden or induction)

- Chrome Plating or E-Nickel

- Hard Coat Anodizing

- Burn Out Plates

Machining Capabilities

Corydon Machine & Tool is a full service products and solutions provider of custom automation machinery, components, and fabrications to a variety of industries.

We place Customer Satisfaction above all by delivering projects with consistency and dependability. As a result, we have built a relationship of trust with our customers. That trust, and the reputation that follows, has to be earned. We welcome the opportunity to build that trust.

Products We Have Manufactured

Various Molds and Dies, Air Conditioning Shafts, Machine Tools and Fixtures, Precision Plate and Gravure Cylinders, Anilox Rolls, Idler Rolls, Steel Cores for Rubber Covering or Lagging, Printing Press Air Mandrels, Doctor Blade Holders and Assemblies, Forged Dies for Automation and Space Industry and more…

Die Making

- Blanking

- Compound

- Extrusion

- Progressive

- Stamping

Fabrication

- Cutting-Laser

- Cutting-Plasma

- Swaging

- Welding/Brazing

Machining

- 5 Axis Machining

- Elec Discharge

- Wire Machining

- Milling

- Milling and Turning

- Turning

Mold Making

- Injection Mold

- Patterns

- Structural Foam

- Thermoform Mold

- Transfer Mold

Repairs / Maintenance

- Compontents/Parts

- Dies/Molds

- Mach & Mach Tool

- Maintenance / Alignment

Capabilities

- Heat Treating

- EDM Plunger & Wire

- Cylindrical Grinding

- Flame Hardening

- Chrome Plating

- Hard-Coat Anodizing

- Blanchard Grinding

- Burn-out Plates

A Client-Centric Culture

Extraordinary Service

Clients choose Corydon Machine & Tool because of extraordinary service. A commitment to CM&T’s client-centric culture has allowed us to build our own process of working hand-in-hand with customers through complex production planning, timeliness and project benchmarks.

”The performance and delivery on projects with Precision, Quality and Expediency has ensured retainable clients for over thirty five years.

Steve YahrausFounder

INNOVATION. CERTIFICATION. SAFETY.

Team Culture

By bringing the best in design, project management, and the skilled trades, we have created a team culture built upon innovation, certification, and safety.

AboutGet A QuoteInnovation

CM&T continually improves our manufacturing practices through the highest possible standards of compliance and certification of employees.

Certification

Certified veteran machinists and welders allow CM&T to ensure a seamless project execution while maintaining the quality that is expected.

Safety

We believe the safety of our team is our responsibility and highest priority. This protocol is essential for the success of our business and yours.

Meeting challenges head on

Quality Control

We will always react quickly and knowingly to project demands and customer needs. At CM&T customers are able to leverage the integrity and accountability through our quality control team that assures all project objectives are met, and allow us to meet the challenge that any project provides.

Your deadline is our priority

Expediency

Meeting delivery deadlines is vital to our customers’ operation. To ensure that they are always fulfilled, CM&T utilizes long term scheduling and production planning. CM&T welcomes the opportunity to earn your trust and deliver you the precision, quality and expediency you expect for your industry.

Project Management

Corydon Machine & Tool Company maintains four simple characteristics that have served as the foundation to the company’s successful longevity in customer satisfaction.